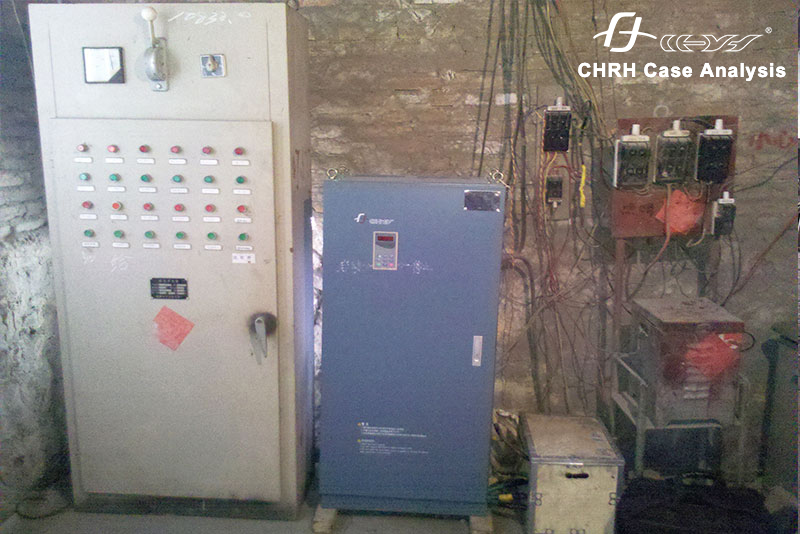

Application Case Of CHRH Variable Frequency Drives In Copper Mining

Introduction:

With the continuous advancement of industrial technology, the mining industry is seeking more efficient and sustainable production methods. Copper, as a crucial industrial raw material, requires a significant amount of energy and equipment for its extraction and processing. Variable frequency drives (VFDs), as a key motor control technology, are being widely applied in equipment like copper mining cone crushers. This article introduces a real case study of CHRH VFDs in copper mining. It demonstrates how their use can improve production efficiency, reduce energy consumption, extend equipment lifespan, and contribute to sustainable development goals.

1. Speed Control

Copper mining cone crushers play a vital role in the ore-crushing process, directly impacting ore-crushing efficiency and production yield. Traditionally, crushers have fixed operating speeds, limiting their effectiveness in processing ores of varying hardness and loads. However, by introducing CHRH VFDs, the operating speed of cone crushers can be precisely adjusted to accommodate different ore types. This means that whether dealing with hard or softer ores, optimal crushing results can be achieved, thereby enhancing production efficiency.

2. Energy Efficiency and Cost Savings

Copper mining, from extraction to ore crushing, typically consumes a substantial amount of electricity. Traditional crushers require a sudden surge of current during startup, which can lead to increased peak loads on the power grid, resulting in higher energy consumption and electricity costs. CHRH VFDs facilitate the smooth startup of cone crushers, mitigating grid disturbances, reducing peak current demands, and lowering energy wastage. Furthermore, CHRH VFDs can dynamically adjust the crusher's operating speed based on actual load requirements, further reducing energy costs.

3. Equipment Protection

Equipment such as cone crushers in ore crushing operations often operates under high loads and impact conditions, subjecting their components to significant stress. Traditional startup methods can lead to mechanical shocks and current surges, increasing the risk of equipment wear and damage. CHRH VFDs, on the other hand, enable smooth startups and shutdowns, minimizing such shocks, extending equipment lifespans, reducing maintenance and repair frequencies, and lowering maintenance costs.

4. Remote Monitoring and Maintenance

CHRH VFDs are equipped with communication interfaces that can be integrated with monitoring systems. This allows for remote monitoring of the entire copper mining process, with real-time data transmission to a central control room, including operational status, current, vibration, and more. In case of anomalies, maintenance personnel can take immediate action, enabling more efficient predictive maintenance. This enhances equipment reliability, safety and reduces downtime.

Conclusion:

The use of CHRH VFDs in equipment like cone crushers for copper mining offers multiple advantages. These include improved production efficiency, energy cost savings, extended equipment lifespan, and reduced maintenance costs, all contributing to a more sustainable production approach. CHRH VFDs have become an indispensable technological tool in the modern copper mining industry, facilitating its transition towards higher efficiency and environmental responsibility.

Solutions

Contact Us

Factory Address

Factory Address

No.196, 12th Wei Road, Economic Development Industrial Zone, Yueqing City, Zhejiang Province, China

Office Address

Office Address

Building No.3, Qianjiang International Times Square, 290 Fuchun Road, Uptown District, Hangzhou City, Zhejiang Province, China

Mailbox

Mailbox

日行千里 —— 虹贯全球